Counter-top height adjustable stool Maintenance: Keep It Looking New

Picture this: your once-pristine counter top height adjustable stool now shows scuff marks on the footrest, stains on the upholstery, and a dull metal base that's lost its shine. After investing in quality commercial seating, the last thing you want is for it to look worn and neglected within months. The good news? With proper maintenance techniques and consistent care routines, your counter top height adjustable stool can maintain its showroom appearance for years, protecting your investment while ensuring a professional atmosphere in your workspace.

Understanding Your Counter Top Height Adjustable Stool Components

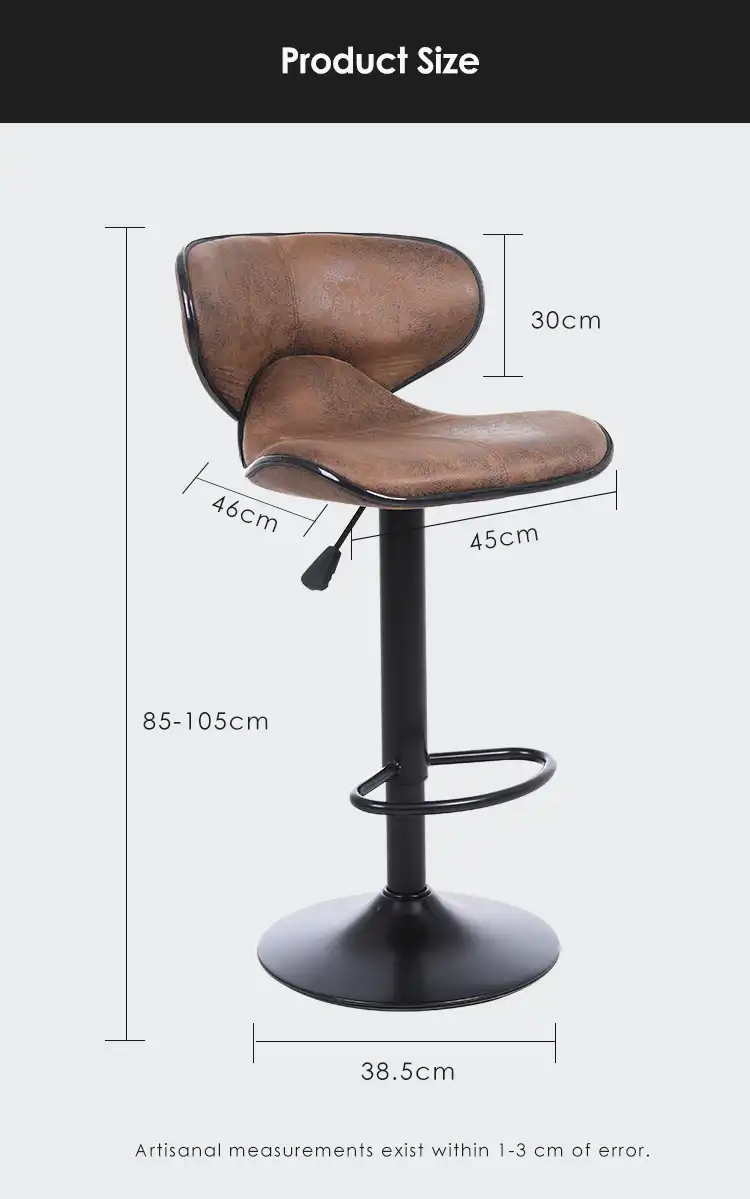

Before diving into maintenance procedures, it's essential to understand the construction of your counter top height adjustable stool. Quality stools from manufacturers like Anji Yibo Furniture Co., Ltd. feature multiple components that each require specific care approaches. The typical stool includes a stainless steel or powder-coated metal base, a gas lift or screw mechanism for height adjustment, a 360-degree swivel seat, commercial-grade upholstery with high-density foam padding, and a non-slip footrest. Each of these elements faces different types of wear and environmental challenges in commercial settings. The base of your counter top height adjustable stool serves as the foundation, typically constructed from durable stainless steel or powder-coated metal that can support up to 300 pounds. This component encounters floor contact, potential moisture exposure, and the stress of constant weight shifts throughout the workday. The height adjustment mechanism, whether gas lift or screw-based, contains precision engineering that enables smooth transitions between the typical 33 to 41-inch range. Regular maintenance of this mechanism prevents sticking, squeaking, or failure that could render the stool unusable. The upholstered seat, often featuring materials like vinyl, fabric, or leather over foam padding (commonly 3.8cm thick with 1.0-1.2cm plywood backing), absorbs the most direct wear from daily use and requires the most frequent cleaning attention to prevent permanent staining and material breakdown.

Material Specifications and Their Maintenance Implications

Professional-grade counter top height adjustable stools incorporate specific materials chosen for durability and comfort in commercial environments. Understanding these specifications helps you implement appropriate maintenance strategies. High-quality models feature seats with 0.8mm thickness half-PU upholstery, providing a balance between comfort and easy cleaning. The construction typically includes double-needle thread stitching on the front and back seams, which prevents unraveling but requires inspection during maintenance to catch any early signs of thread failure. The assembly uses precise fastening with screws measuring 6x14mm, strategically placed to maintain structural integrity while allowing for periodic tightening as part of your maintenance routine. The foam padding density directly impacts both comfort and maintenance needs for your counter top height adjustable stool. Higher-density foam (typically 3.8cm in commercial models) resists compression and maintains its shape longer than lower-grade alternatives, but it also requires more careful cleaning to avoid saturation that could lead to mold or mildew development. The plywood backing, usually 1.0 to 1.2cm thick, provides structural support while remaining lightweight enough for the adjustment mechanism to function smoothly. This backing must remain dry during cleaning to prevent warping or delamination that could compromise the seat's stability and comfort over time.

Daily Maintenance Routines for Counter Top Height Adjustable Stools

Establishing a consistent daily maintenance routine forms the foundation of long-term stool preservation. In commercial kitchens, healthcare facilities, or laboratory environments where counter top height adjustable stools see heavy use, end-of-day cleaning prevents minor issues from becoming major problems. Start by wiping down the upholstered seat with a soft, slightly damp microfiber cloth to remove surface dust, crumbs, and light spills. This simple action, taking less than two minutes per stool, prevents dirt from becoming ground into the fabric or vinyl upholstery where it becomes significantly harder to remove and can accelerate material degradation. The metal components of your counter top height adjustable stool require daily attention to maintain their professional appearance and prevent corrosion. Use a clean, dry cloth to wipe the base, gas lift cylinder, and any exposed metal hardware, removing fingerprints, moisture, and dust that accumulate throughout the workday. Pay particular attention to the footrest, which experiences constant contact with shoes that can transfer oil, salt, moisture, and abrasive particles. A quick wipe of the footrest prevents the buildup of grime that not only looks unprofessional but can also become slippery and pose a safety hazard. In humid environments or areas near sinks and dishwashers, this daily drying is especially critical for preventing rust formation on any exposed metal surfaces.

Inspection During Daily Cleaning

While performing daily cleaning of your counter top height adjustable stool, conduct a quick visual and functional inspection that takes only seconds but can identify problems before they require expensive repairs or replacement. Test the swivel function by gently rotating the seat through its full 360-degree range, listening for any grinding, clicking, or squeaking sounds that might indicate the need for lubrication or bearing maintenance. Check the height adjustment mechanism by raising and lowering the seat through its full range, ensuring it moves smoothly and locks securely at various positions. Resistance, sticking, or failure to hold position indicates the mechanism needs attention before it fails completely during use. Examine all visible fasteners and connection points on your counter top height adjustable stool for any signs of loosening, which is common in commercial environments with heavy daily use. The typical stool uses multiple 6x14mm screws at critical stress points, and these can gradually loosen from the constant weight shifts and movement of users throughout the day. Running your hand along seams and edges helps identify any protruding screw heads or loose panels that could catch clothing or cause injury. Early detection of these issues allows for quick tightening during routine maintenance rather than waiting for a component to fail, which could damage other parts of the stool or even cause a user accident.

Deep Cleaning Different Upholstery Types

The upholstery material on your counter top height adjustable stool determines the specific cleaning approach required for deep maintenance. Vinyl upholstery, a popular choice for commercial environments due to its durability and water resistance, responds well to mild soap and water solutions for routine deep cleaning. Mix a few drops of gentle dish soap in warm water, dampen a soft cloth (never saturate it), and wipe the entire seat surface using circular motions. This method effectively removes body oils, food residues, and general grime that accumulate over time. After cleaning with the soap solution, immediately wipe the surface with a clean damp cloth to remove all soap residue, then dry thoroughly with a soft towel to prevent water spots and maintain the vinyl's protective finish. Fabric upholstered counter top height adjustable stools require more careful cleaning to avoid damage and ensure thorough drying. Begin by vacuuming the fabric with an upholstery attachment to remove loose dirt, dust, and crumbs that have settled into the weave. This prevents these particles from turning into mud when you apply cleaning solutions. For spot cleaning specific stains, identify the fabric's cleaning code (usually found on a tag or in the manufacturer's documentation) which indicates whether to use water-based (W), solvent-based (S), water or solvent (W/S), or no liquid cleaners (X). Most commercial fabrics used on professional counter top height adjustable stools carry a W or W/S code, allowing for water-based cleaning. Apply a small amount of upholstery cleaner to a white cloth (colored cloths can transfer dye) and blot the stain from the outside edges toward the center to prevent spreading.

Leather and Faux Leather Care

Genuine leather seats on premium counter top height adjustable stools require specialized care to maintain their luxurious appearance and prevent cracking or drying. Never use standard household cleaners or excessive water on leather, as these can strip the natural oils and cause irreversible damage. Instead, invest in a quality leather cleaner specifically formulated for furniture use. Apply a small amount to a soft cloth and gently wipe the leather surface in sections, working the cleaner into the material without saturating it. Follow immediately with a leather conditioner applied in the same manner, which replenishes the natural oils and keeps the leather supple. This conditioning step is particularly important in dry environments or climate-controlled spaces where air conditioning and heating can accelerate leather drying. Faux leather or polyurethane upholstery on counter top height adjustable stools offers easier maintenance than genuine leather while still providing an upscale appearance. These materials resist water and stains effectively, making them ideal for busy commercial environments. For regular deep cleaning, use the same mild soap and water approach as with vinyl, but be even more gentle to avoid scuffing or scratching the surface finish. Faux leather can develop a worn, shiny appearance in high-contact areas over time, which unfortunately cannot be reversed, but proper cleaning slows this process considerably. After cleaning, some users apply a very light coat of furniture polish or specialized faux leather conditioner to restore luster, though this should be done sparingly as excess product can leave a sticky residue that attracts dirt.

Maintaining the Height Adjustment Mechanism

The gas lift or hydraulic cylinder that enables height adjustment in your counter top height adjustable stool represents one of the most critical components for functionality and safety. This mechanism operates through a sealed cylinder containing compressed gas (typically nitrogen) that supports the seat weight while allowing smooth height changes. Over time, this system can develop issues from normal wear, dust accumulation, or seal degradation. To maintain optimal function, regularly wipe the exposed cylinder shaft with a clean, dry cloth to remove dust and debris that could scratch the internal seals when the cylinder extends and retracts. Never use oil or lubricants on the visible shaft, as these attract more dirt and can damage the internal seals. If your counter top height adjustable stool begins showing signs of mechanism problems such as slow sinking, difficulty adjusting height, or complete failure to hold position, first ensure the issue isn't simply debris interfering with the trigger mechanism. Many stools feature a lever or paddle under the seat that activates the gas lift, and dust, food particles, or other debris can prevent this trigger from fully engaging or releasing. Clean around this trigger mechanism with a soft brush and compressed air if available. Check that nothing has become wedged between the trigger and the seat frame that could block its movement. In commercial settings with multiple stools, consider implementing a weekly deep clean of all adjustment mechanisms to prevent these issues from developing.

Swivel Function Maintenance

The 360-degree swivel capability of your counter top height adjustable stool relies on a bearing system between the seat and the base column. This bearing allows smooth rotation while supporting the full weight of the user and any movement forces they generate. Over time, this bearing can accumulate dust, dirt, and debris that create friction, leading to grinding sounds, difficulty rotating, or complete binding. To maintain smooth swivel action, periodically turn the stool upside down (being careful of the gas lift cylinder) and clean the visible bearing surfaces with a dry cloth. For stubborn dirt buildup, use a slightly damp cloth followed immediately by thorough drying. Most commercial-grade counter top height adjustable stools feature sealed bearings that don't require lubrication, but if your particular model has accessible bearing surfaces and the manufacturer recommends lubrication, use only a dry lubricant like graphite powder or specialized bearing grease. Avoid oil-based lubricants that attract dust and create a sticky mess that actually increases friction over time. Apply lubricant sparingly – a tiny amount goes a long way – and work it into the bearing by rotating the seat several times in both directions. Wipe away any excess lubricant that emerges, as this excess will only attract contaminants. In environments with heavy use, check the swivel function monthly and address any changes in smoothness immediately to prevent bearing damage.

Base and Footrest Care

The base of your counter top height adjustable stool, whether stainless steel or powder-coated metal, provides stability while creating the overall aesthetic impression. Stainless steel bases resist corrosion naturally but still require cleaning to maintain their attractive finish and prevent the buildup of oils, fingerprints, and grime that can dull the surface. For routine cleaning, wipe the base with a microfiber cloth dampened with water and a small amount of mild dish soap, following the grain of the metal finish if visible. Rinse with a clean damp cloth and immediately dry with a soft towel to prevent water spots. For a showroom shine, specialized stainless steel cleaners and polishes can restore luster, though these aren't necessary for routine maintenance. Powder-coated metal bases on counter top height adjustable stools offer excellent durability and color options but can chip if struck by hard objects. Inspect the powder coating regularly for any chips or scratches that expose the underlying metal. Small chips can be addressed with touch-up paint matched to the original color, which prevents rust from starting at these vulnerable points. Clean powder-coated surfaces with mild soap and water, avoiding abrasive cleaners or scrub pads that could scratch the coating. If you notice the powder coating becoming dull or chalky, this indicates UV damage or chemical exposure, and while the coating will still protect the metal, the aesthetic appearance may require professional refinishing for high-visibility installations.

Footrest Maintenance Strategies

The footrest or foot ring on your counter top height adjustable stool experiences some of the hardest wear of any component, as it constantly contacts shoes that carry dirt, moisture, salt, and abrasive particles from the floor. Daily wiping with a damp cloth removes these contaminants before they can cause scratching or corrosion. In wet environments like commercial kitchens or bars, the footrest may develop rust or corrosion spots despite regular cleaning, especially if the protective coating becomes damaged. Address these spots immediately by cleaning with a mixture of equal parts white vinegar and water applied with a soft cloth, which removes light rust without damaging surrounding surfaces. For stubborn rust on the footrest of your counter top height adjustable stool, a gentle abrasive approach may be necessary. Crumple aluminum foil into a ball, dip it in water (or better yet, the vinegar-water solution), and gently rub the rusted area in circular motions. The aluminum acts as a mild abrasive while the chemical reaction between aluminum and rust helps lift the corrosion without damaging the underlying metal. After removing rust, thoroughly dry the area and consider applying a thin coat of clear nail polish or specialized metal sealant to prevent recurrence. In high-traffic commercial environments, implementing protective measures like regular applications of furniture wax or metal polish creates a barrier against moisture and contaminants that cause rust.

Structural Integrity and Hardware Inspection

Beyond cosmetic maintenance, ensuring the structural integrity of your counter top height adjustable stool is essential for user safety and longevity. The typical stool uses multiple fasteners, including 6x14mm screws at critical connection points, to hold the seat, base, and mechanism together. These fasteners experience constant stress from user weight, movement, and the mechanical action of height adjustment and swiveling. Over time, vibration and repeated stress cycles can cause these fasteners to loosen, which not only affects stability but can also cause accelerated wear on the components they connect. Implement a monthly inspection routine where you check each visible screw and bolt, tightening any that have loosened even slightly. When tightening hardware on your counter top height adjustable stool, use appropriate tools that fit properly to avoid stripping screw heads or damaging the surrounding material. A properly sized Phillips or Allen key provides the best results, and applying firm, steady pressure rather than excessive force prevents over-tightening that could strip threads or crack components. If you find the same screws repeatedly loosening despite regular tightening, consider applying a small drop of thread-locking compound (available in various strength grades) to the threads before reinstalling the screw. This compound creates friction that prevents loosening while still allowing future disassembly if needed for repairs or replacement. Choose a medium-strength compound for most applications, as permanent thread lockers make future maintenance extremely difficult.

Wobble Detection and Correction

A wobbly counter top height adjustable stool not only feels uncomfortable and unsafe for users but also indicates a problem that will worsen if not addressed. Common causes of wobbling include loose fasteners, worn bearings, bent components, or uneven floor surfaces. To diagnose wobble, place the stool on a known-level surface and apply weight to the seat while checking for movement at the base. If the base itself rocks, check that all feet or the base ring sit flat on the floor. Some models include adjustable feet that can compensate for minor floor irregularities, which should be adjusted until the base sits stable without rocking. If your counter top height adjustable stool wobbles even on a level surface with tight fasteners and properly adjusted feet, the issue may be a bent gas lift cylinder or damaged bearing. These problems typically require professional repair or component replacement rather than DIY fixes. However, before concluding that replacement is necessary, ensure the seat is properly centered on its mounting points, as some models allow slight shifting during assembly or after prolonged use that can create an off-balance condition. Consult the manufacturer's assembly instructions or contact technical support for guidance on proper seat alignment specific to your model. Attempting to bend or force components into alignment without proper knowledge can cause additional damage and create safety hazards.

Preventing Common Damage Scenarios

Understanding how damage occurs allows you to implement preventive strategies that significantly extend the life of your counter top height adjustable stool. One of the most common causes of premature wear is users standing on the seat or footrest when reaching for high objects. While quality stools like those from Anji Yibo Furniture Co., Ltd. can support their rated weight capacity when used as designed, standing concentrates force in ways the structure wasn't engineered to handle, potentially bending the gas lift cylinder, stressing welds, or cracking the seat structure. Post clear signage in commercial environments reminding users to use proper ladders or step stools for overhead access. Sharp objects represent another significant threat to your counter top height adjustable stool's longevity, particularly regarding the upholstered seat. Keys, pens, tools, and even studded clothing or accessories can puncture or tear vinyl, fabric, or leather surfaces, creating entry points for dirt and moisture that accelerate deterioration. In environments where users may carry such items, consider implementing a policy of emptying pockets before sitting or providing designated storage for sharp objects. Regular inspections help identify small punctures or tears before they expand, allowing for early repair with patches or specialized adhesives designed for upholstery materials. Addressing these small damages immediately costs far less than replacing entire seats.

Chemical and Environmental Protection

Commercial environments often expose counter top height adjustable stools to chemicals, cleaning products, and environmental conditions that can damage materials if not properly managed. Bleach, ammonia, strong solvents, and acidic cleaners can discolor, crack, or weaken upholstery materials, metal finishes, and plastic components. Ensure that any cleaning staff in your facility understand which products are safe to use on seating. Create a simple reference chart posted near cleaning supply storage that clearly indicates approved cleaning products for different stool components. When spills of potentially damaging substances occur, immediate cleanup with appropriate neutralizing agents minimizes damage. Temperature extremes and UV exposure also affect counter top height adjustable stool longevity, though these factors are often overlooked. Direct sunlight streaming through windows can fade and dry out upholstery materials, particularly leather and certain fabrics, while the heat accelerates the breakdown of foam padding. In spaces with significant natural light, consider window treatments that filter UV rays, or position stools away from direct sun exposure when possible. Similarly, positioning stools near heat sources like ovens, radiators, or heating vents accelerates material aging. Cold temperatures make some materials brittle and prone to cracking, particularly vinyl and certain plastics. Maintaining a moderate, consistent temperature range (typically 60-75°F or 15-24°C) helps all materials age gracefully and maintain their designed properties.

Storage and Off-Season Care

For establishments that experience seasonal closures or significantly reduced operations, proper storage of counter top height adjustable stools protects your investment during periods of non-use. Before storing, thoroughly clean all surfaces following the material-specific guidelines discussed earlier, ensuring complete dryness to prevent mold, mildew, or rust formation during storage. Inspect each stool for any damage or needed repairs, addressing these issues before storage rather than discovering them when you need the stools again. This proactive approach allows repairs during slow periods rather than rushed fixes when reopening. Cover each counter top height adjustable stool with breathable fabric covers or sheets during storage, avoiding plastic that can trap moisture and create condensation that damages materials. Store in a climate-controlled environment when possible, avoiding extreme temperatures, high humidity, or direct sunlight that can degrade materials even when not in use. If storing multiple stools, avoid stacking them directly on top of each other, which can crush foam padding or damage finishes. Instead, arrange them with adequate spacing or use protective layers between units if stacking is unavoidable. Periodically check stored stools (monthly is ideal) for any signs of pest activity, moisture accumulation, or other storage-related issues that require intervention.

Professional Maintenance and When to Seek Help

While regular owner-performed maintenance keeps your counter top height adjustable stool in excellent condition, certain situations require professional assessment or repair. If the gas lift mechanism fails completely, attempting to disassemble or repair it yourself poses safety risks from the pressurized gas it contains. Professional furniture repair technicians or the manufacturer's service department can safely replace failed gas lifts with appropriate replacement parts. Similarly, significant upholstery damage like large tears, seam failures, or extensive staining that resists cleaning efforts may warrant professional reupholstery, which can often cost less than replacing the entire stool while providing an opportunity to refresh the appearance with new fabric or color choices. Structural damage to the base, particularly cracks in welds or metal fatigue, requires professional evaluation to determine whether repair is feasible and safe. A compromised base can fail catastrophically, causing injury to users, so never attempt to weld repairs yourself unless you have proper training and equipment. For establishments with large numbers of counter top height adjustable stools, establishing a relationship with a commercial furniture maintenance service provides access to expertise, bulk pricing on replacement parts, and often preventive maintenance programs that catch problems before they cause failures. These services can perform thorough periodic inspections, coordinate repairs, and maintain detailed service records that help track the lifecycle of your seating inventory.

Conclusion

Maintaining your counter top height adjustable stool requires consistent attention to cleaning, inspection, and preventive care across all components. By implementing daily wiping routines, monthly hardware checks, and periodic deep cleaning appropriate to your upholstery type, you protect your investment while ensuring a professional appearance and safe operation. The relatively small time investment in proper maintenance delivers substantial returns through extended service life, maintained aesthetics, and enhanced user satisfaction in your commercial environment.

Cooperate with Anji Yibo Furniture Co., Ltd.

When you're ready to invest in High Quality counter top height adjustable stools that combine ergonomic design with durability, Anji Yibo Furniture Co., Ltd. stands as your trusted China counter top height adjustable stool manufacturer with 14 years of specialized experience in chair production. Located in Anji, Zhejiang, the hometown of chairs, our 6000-square-meter facility employs advanced equipment and skilled personnel to deliver container loads of premium seating monthly to clients worldwide. As a leading China counter top height adjustable stool supplier, we specialize in bar chairs, dining chairs, leisure chairs, gaming chairs, and office chairs, all designed with ergonomic comfort, fantastic value, and enduring quality that meets the highest international standards.

Our professional R&D team supports OEM and ODM projects, offering customized solutions tailored to your brand requirements and market preferences. With counter top height adjustable stools for sale that feature competitive wholesale pricing without compromising quality, we provide the perfect balance of affordability and excellence. Every product carries our warranty, and our experienced sales team responds to inquiries within 24 hours, demonstrating our commitment to comprehensive service. As an established China counter top height adjustable stool factory, we've exported our products to 70 countries, specializing in European and American retro style and light luxury craftsmanship. Contact us today at yb@ajyibo.com to discuss your seating needs and discover why businesses worldwide trust our manufacturing expertise and competitive counter top height adjustable stool prices for their commercial environments.

References

1. National Association of Furniture Manufacturers. "Commercial Seating Maintenance Standards and Best Practices." Journal of Furniture Care, 2024.

2. Anderson, Michael J. "Material Science in Modern Upholstery: Maintenance Requirements for Commercial Applications." Textile Technology Review, 2023.

3. Professional Furniture Maintenance Association. "Hydraulic Mechanism Care and Safety Guidelines for Adjustable Seating." Technical Manual Series, 2024.

4. Chen, Wei and Roberts, Sarah. "Corrosion Prevention in Commercial Metal Furniture: A Comprehensive Guide." International Journal of Furniture Engineering, 2023.

5. European Furniture Care Institute. "Upholstery Cleaning Codes and Recommended Maintenance Protocols." EFCI Standards Publication, 2024.