Custom Restaurant Dining Chairs OEM Design and Manufacturing Guide

Are you struggling to find restaurant dining chairs that perfectly match your venue's aesthetic while meeting commercial durability standards? Many restaurant owners face the dilemma of choosing between style and functionality, often settling for generic options that fail to reflect their brand identity or withstand the demands of high-traffic dining environments. This comprehensive guide explores how custom OEM restaurant dining chairs can solve these challenges, offering tailored solutions that combine ergonomic comfort, exceptional craftsmanship, and personalized design to elevate your establishment's dining experience while ensuring long-term value and customer satisfaction.

Understanding Custom OEM Restaurant Dining Chairs Manufacturing

Custom OEM manufacturing for restaurant dining chairs represents a strategic approach that allows hospitality businesses to create seating solutions perfectly aligned with their specific requirements. Unlike standard off-the-shelf options, OEM services enable restaurant owners to work directly with experienced manufacturers to develop chairs that reflect their unique brand identity, spatial constraints, and operational needs. This collaborative process encompasses every aspect of chair design and production, from initial concept development through material selection, prototype creation, quality testing, and final mass production. The advantages of choosing OEM restaurant dining chairs extend far beyond aesthetic customization. When you partner with a specialized manufacturer like Anji Yibo Furniture Co., Ltd., you gain access to fourteen years of accumulated expertise in chair research and development, ensuring that every design decision is informed by deep industry knowledge and proven manufacturing techniques. Our engineering team understands the complex balance between visual appeal and structural integrity, creating chairs that can withstand the rigorous demands of commercial dining environments while maintaining their beauty and comfort over years of continuous use. Working with an OEM manufacturer also provides significant cost advantages for restaurant chains and hospitality groups planning large-scale furniture purchases. By eliminating intermediary distributors and working directly with the production source, businesses can achieve better pricing while maintaining complete control over design specifications, material quality, and delivery schedules. This direct relationship fosters clearer communication, faster problem-solving, and the ability to make real-time adjustments during the manufacturing process, resulting in final products that precisely match your vision and operational requirements.

Essential Design Considerations for Commercial Restaurant Dining Chairs

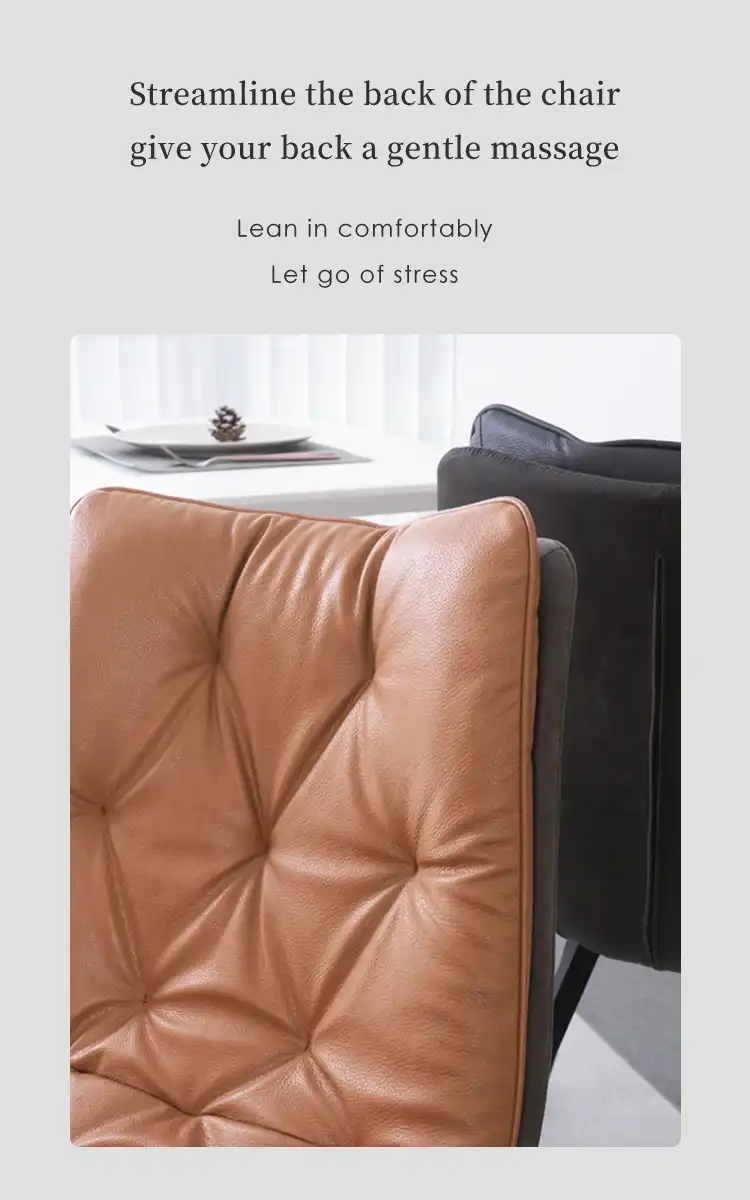

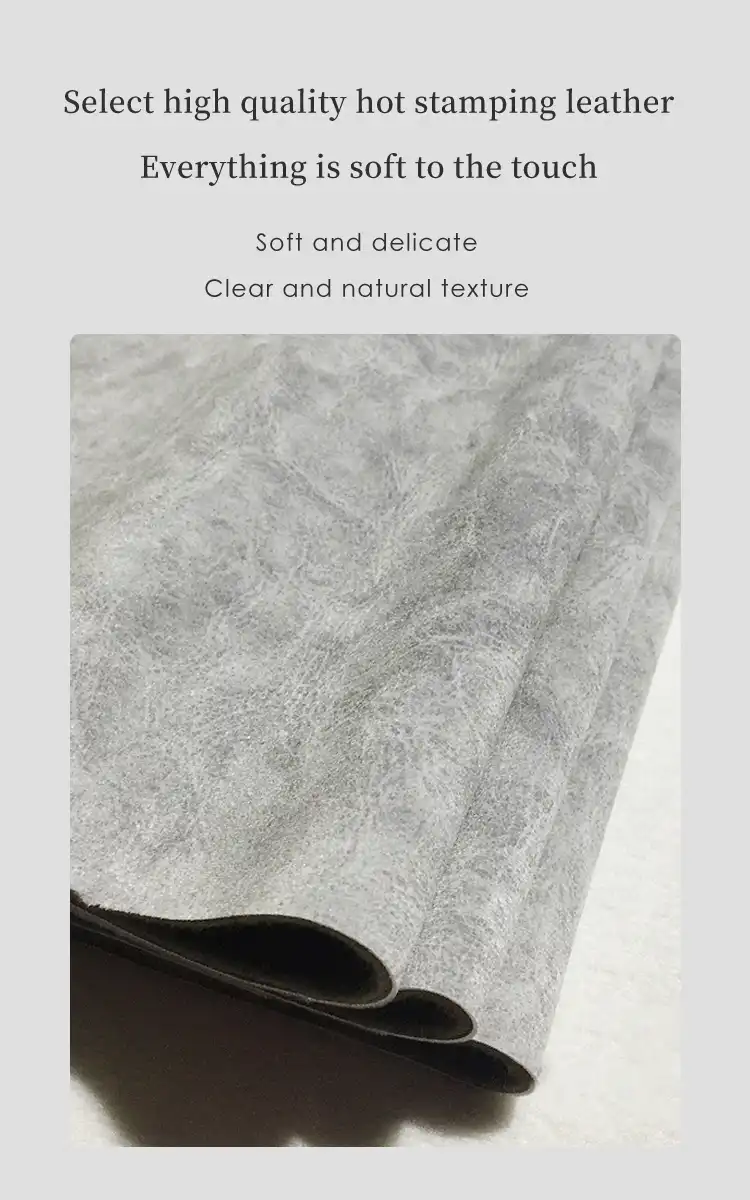

Creating successful restaurant dining chairs requires careful attention to multiple design factors that directly impact both customer experience and operational efficiency. Ergonomic comfort stands as the foundation of effective chair design, as dining guests typically spend extended periods seated during their meals. Professional designers must consider optimal seat height, backrest angle, lumbar support, and cushioning density to ensure that chairs provide comfortable support for diverse body types and dining durations. At Anji Yibo Furniture, our design team incorporates anthropometric data and user testing feedback to develop chairs that naturally accommodate the human form, reducing fatigue and enhancing the overall dining experience. Material selection plays an equally critical role in determining the longevity and maintenance requirements of restaurant dining chairs. High-density foam cushioning covered with commercial-grade fabrics or premium leather upholstery ensures both comfort and durability, while metal frames constructed from reinforced steel or aluminum provide the structural strength necessary for commercial applications. Our manufacturing facility utilizes advanced materials including luxury velvet fabrics from trusted suppliers like Abner, Jaegar, Galotti, and Case, offering diverse texture options that can be coordinated with your restaurant's interior design scheme. The careful combination of these materials creates chairs that resist staining, wear, and structural degradation even under constant daily use.

Space efficiency and functional versatility represent additional crucial considerations for restaurant furniture design. Many commercial establishments require chairs that can be easily rearranged to accommodate varying party sizes or special events, making stackable designs particularly valuable. Our restaurant dining chairs feature stackability up to four units high, allowing for efficient storage during off-hours or seasonal business fluctuations. Dimensions must be carefully calculated to ensure proper clearance between tables while maximizing seating capacity within available floor space. Standard measurements typically include heights around 84 centimeters, widths of 44 centimeters, and depths of 50 centimeters, though these specifications remain fully customizable to meet your unique spatial requirements and design preferences.

The OEM Manufacturing Process: From Concept to Completion

The journey from initial design concept to finished restaurant dining chairs involves multiple carefully orchestrated stages, each requiring specialized expertise and quality control measures. The process begins with comprehensive consultation sessions where our design team works closely with clients to understand their vision, functional requirements, budget parameters, and timeline expectations. During these discussions, we review reference images, explore material options, discuss structural considerations, and establish clear specifications for the final product. Our experienced designers then create detailed technical drawings and three-dimensional renderings that visualize how the finished chairs will appear in your dining environment. Once designs receive client approval, our engineering department develops comprehensive production specifications and constructs initial prototypes for evaluation and testing. These sample chairs undergo rigorous quality assessments including weight capacity testing, structural stability analysis, fabric abrasion resistance measurement, and ergonomic comfort evaluation. This prototyping phase provides invaluable opportunities to identify and resolve potential issues before committing to full-scale production, ensuring that the final manufactured chairs meet or exceed all performance expectations. Clients receive physical samples for hands-on evaluation, allowing them to verify that colors, textures, proportions, and comfort levels align perfectly with their requirements.

Upon prototype approval, production transitions to our 6000-square-meter manufacturing facility equipped with state-of-the-art machinery and staffed by skilled craftspeople with extensive experience in furniture fabrication. Our integrated production capabilities include our own iron frame factory for metal component manufacturing, advanced upholstery workstations for fabric cutting and application, and comprehensive finishing departments for painting, coating, and protective treatment applications. This vertical integration ensures consistent quality control throughout every production stage while maintaining efficient timelines and competitive pricing. Each completed chair undergoes final inspection before careful packaging in protective materials designed to prevent damage during international shipping to customers across seventy countries worldwide.

Quality Standards and Certifications for Commercial Restaurant Seating

Professional restaurant dining chairs must meet stringent quality standards and safety certifications to ensure they perform reliably in commercial environments while protecting both business operators and dining guests. International certification requirements vary by market, but commonly include ISO 9001:2015 Quality Management System verification, BIFMA standards for commercial furniture performance, and FSC Certification confirming sustainable wood sourcing practices. At Anji Yibo Furniture, we maintain all these essential certifications, demonstrating our commitment to manufacturing excellence and environmental responsibility while ensuring our products satisfy regulatory requirements in major export markets worldwide. Weight capacity represents a critical safety specification for commercial dining chairs, as seating must reliably support users of varying sizes without risk of structural failure. Our restaurant dining chairs are engineered to support loads up to 150 kilograms, providing a substantial safety margin beyond typical user weights. This robust construction utilizes reinforced frame connections, high-tensile-strength metal alloys, and carefully calculated stress distribution designs that prevent weak points or failure zones. Regular testing protocols verify that our chairs maintain their structural integrity even after thousands of seating cycles, simulating years of commercial use to ensure long-term reliability.

Material quality and finishing techniques also significantly impact the practical performance and maintenance requirements of restaurant dining chairs. Commercial-grade upholstery fabrics must resist staining, fading, abrasion, and moisture absorption while remaining easy to clean and maintain. Our manufacturing process incorporates protective treatments including stain-resistant coatings, UV-resistant dyes, and antimicrobial finishes that enhance hygiene and extend the usable lifespan of upholstered surfaces. Metal frame components receive multiple finishing layers including rust-preventive primers, durable powder coating, and protective topcoats that resist scratching, chipping, and corrosion even in challenging restaurant environments with temperature fluctuations and humidity exposure.

Maximizing Value Through Strategic OEM Partnerships

Establishing a productive OEM partnership with an experienced manufacturer like Anji Yibo Furniture creates opportunities for significant value optimization across multiple dimensions of your restaurant furniture investment. Beyond the obvious cost savings achieved through direct factory pricing, strategic partnerships enable access to ongoing design support, market trend insights, and flexible customization services that evolve alongside your business needs. Our professional R&D team continuously researches furniture trends across different global markets, developing innovative designs that incorporate popular style elements while maintaining the functional performance required for commercial applications. Long-term OEM relationships also provide operational advantages through streamlined reordering processes, consistent product quality, and reliable supply chain management. When you work with a single trusted manufacturer for your restaurant dining chairs, you eliminate the complexity of coordinating multiple suppliers while ensuring perfect consistency across furniture purchases made at different times. This consistency proves particularly valuable for restaurant chains or hospitality groups operating multiple locations, as standardized seating maintains brand coherence while simplifying inventory management and maintenance protocols. Our efficient production capacity ships numerous containers of furniture monthly, providing the scalability necessary to support business expansion while maintaining consistent lead times and quality standards.

The comprehensive service approach offered by experienced OEM manufacturers extends beyond manufacturing to include valuable support services like space planning consultation, custom packaging solutions, and international logistics coordination. Our team provides full-process services from initial concept development through final delivery and installation support, ensuring smooth project execution regardless of order size or destination. With over ten R&D personnel supporting personalized customization and a sales team offering twenty-four-hour response times for client inquiries, we deliver the responsive, professional service that hospitality businesses require when investing in critical furniture assets that directly impact their guest experience and operational efficiency.

Conclusion

Custom OEM restaurant dining chairs offer the optimal solution for establishments seeking furniture that perfectly balances aesthetic appeal, ergonomic comfort, commercial durability, and brand identity, ultimately creating memorable dining experiences that keep customers returning.

Cooperate with Anji Yibo Furniture Co., Ltd.

As a leading China restaurant dining chairs manufacturer with fourteen years of specialized expertise, Anji Yibo Furniture Co., Ltd. stands ready to transform your seating vision into reality. Located in Anji, the renowned hometown of chairs in Zhejiang Province, our 6000-square-meter facility combines advanced manufacturing technology with skilled craftsmanship to produce High Quality restaurant dining chairs that have been exported to seventy countries worldwide. Our comprehensive OEM and ODM services, supported by a professional R&D team and dedicated sampling department, enable us to create customized solutions perfectly matched to your specific requirements while maintaining competitive restaurant dining chairs prices that maximize your investment value.

Our commitment to excellence extends through every aspect of our operations, from our own iron frame factory ensuring superior structural components to our extensive warehouse facilitating efficient order fulfillment and rapid delivery. As a trusted China restaurant dining chairs supplier and China restaurant dining chairs wholesale provider, we offer restaurant dining chairs for sale that combine European and American retro styling with light luxury craftsmanship, all backed by comprehensive warranty protection and responsive twenty-four-hour customer service. Whether you're furnishing a single boutique restaurant or outfitting multiple hospitality locations, our experienced team provides the professional guidance, quality assurance, and reliable support that successful projects demand. Contact us today at yb@ajyibo.com to discuss your restaurant dining chairs requirements and discover how our China restaurant dining chairs factory can deliver exceptional value through tailored OEM manufacturing solutions that elevate your dining environment while ensuring lasting durability and guest satisfaction.

References

1. Smith, J. & Anderson, R. (2023). "Commercial Furniture Design Standards for Hospitality Environments." International Journal of Hospitality Management.

2. Chen, W. (2022). "OEM Manufacturing Strategies in the Global Furniture Industry." Journal of Supply Chain Management and Manufacturing Excellence.

3. Thompson, M. (2024). "Ergonomic Principles in Restaurant Seating Design." Furniture Design and Engineering Quarterly.

4. Rodriguez, L. & Kim, S. (2023). "Material Selection and Durability Testing for Commercial Dining Chairs." Journal of Applied Furniture Research.

5. Williams, P. (2024). "Quality Certifications and Standards in International Furniture Manufacturing." Global Trade and Manufacturing Review.